my notes/key points from it:

“We even put potted plants in the first cell just to show how different the new look was.”

“50 percent. Everything can be cut by 50 percent.” Later they told us they said 50 percent because they didn’t think we would want to hear the real number. We liked that as we were only thinking about 30 percent

“listen and learn. Don’t push back. We found right away that lean (Just-inTime back then) was “learn-by-doing” and we wanted to learn.”

“Mark helped us initially in finance by moving us away from standard cost accounting and toward something similar to what is now called lean accounting, and later became instrumental in creating/running the Danaher Business System (DBS). Switching to lean accounting was another big lesson as it allowed us to finally see what was going on and didn’t fight lean as standard cost accounting does. It also created great productivity in finance as Mark was able to go from 25 to 9 people and close the books in a day and a half.”

“all leaders need to emerge themselves in the details of lean and become lean experts themselves if they want to have a successful lean turnaround.”

“learning was the greatest strategic weapon we had ever seen.”

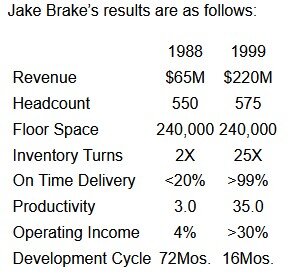

“cut your lead times from weeks to days, increase your productivity, drastically improve your quality and free up over half your floor space by removing the waste from your operations then you would have a huge strategic advantage.”

“A lot of times things didn’t work well at first (in fact most of the time) but we never let it go back to what it was. We just kept pushing till we solved the problems and made it work.”

“we involved the union in everything we did. We were always honest and up front with them. We treated them as equal partners.

we kept proving that every move we made was better for our work force we eventually formed a great relationship. We knew that the best ideas for removing the waste would come from the people doing the work, and that always proved to be true.”

“the Presidents of all 13 Danaher companies to be the lean drivers in their own companies. To do this we had to teach them lean… create the Presidents Kaizen.”

“all the Presidents to participate in a three-day kaizen every six weeks. They weren’t too happy about this at first but the gains we got every time were so big that this quickly changed.”

“Mark DeLuzio created the M&A integration process as well as the due diligence process as it related to DBS. And along with Larry Culp, Danaher CEO (and now the CEO of GE), developed the strategic planning process for all of Danaher”

Read the full article. In a few days, re-read it.